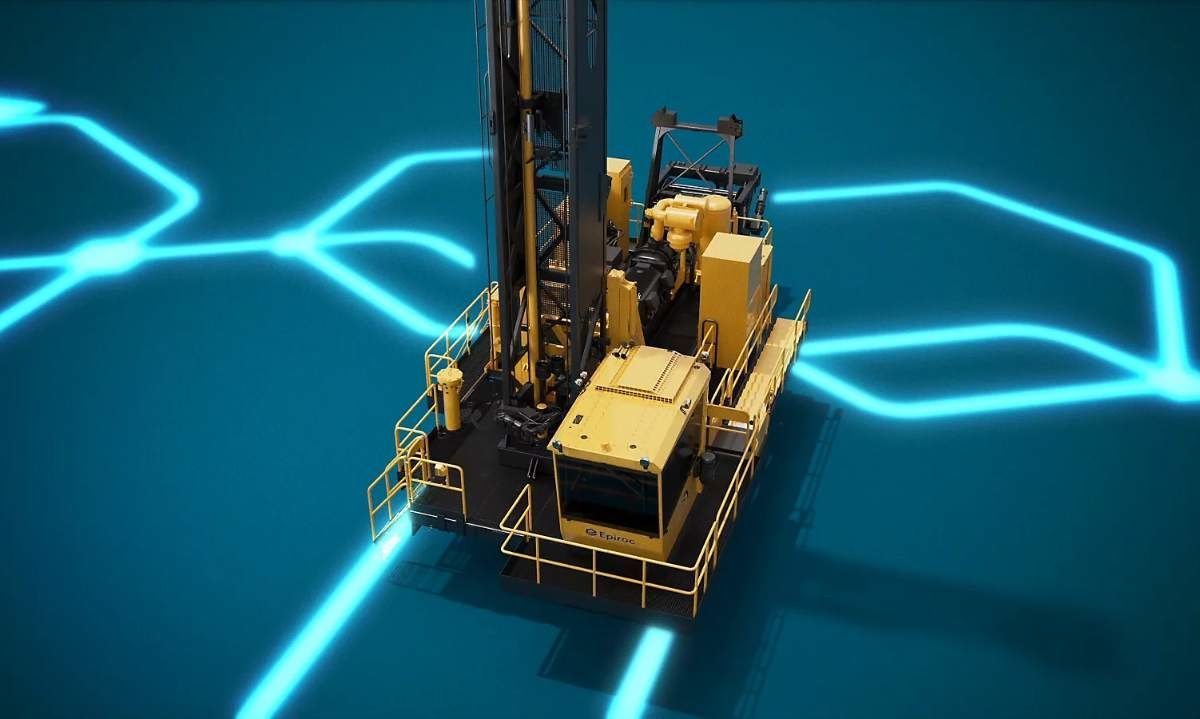

Introducing the Pit Viper 271 XC E, Pit Viper 275 XC E, and Pit Viper 291 E blasthole drill rigs. With the release of these three drills, Epiroc now provides electric alternatives for each drill in the Pit Viper series.

Epiroc announced the launch of its latest electric-driven drills, the Pit Viper 271 XC E, Pit Viper 275 XC E, and the Pit Viper 291 E. Part of its Smart and Green Series, Epiroc's electric-driven Pit Viper drills deliver the same groundbreaking performance with zero exhaust emissions, zero fuel consumption, and a lower carbon footprint.

The Pit Viper 271 XC E is capable of drilling single-pass holes up to 18 m (59 ft) with diameters up to 270 mm (10-5/8 in). The Pit Viper 275 XC E effortlessly handles single-pass holes up to 11 m (37 ft) with diameters reaching 270 mm (10-5/8 in). Both drills can be configured with the XC package (Xtra Capacity) to provide 85,000 lb (42.5 tons) bit load capacity.

The Pit Viper 291 E delivers a powerful performance, capable of drilling single-pass holes up to 18 m (59 ft) with diameters up to 280 – 311 mm (11 – 12 ¼ in). All three rigs are supported by a substantial 42-ton (80,000 lb) bit load capacity that ensures reliable and effective drilling.

Epiroc's latest electric-driven blasthole drills are designed for an era of cleaner and more sustainable operations, offering cutting-edge automation features that optimize productivity and enhance safety and accuracy through live work elimination.

"These electric-driven Pit Viper drills exemplify Epiroc’s unwavering commitment to accelerate change in the mining industry."

Cynthia Rodriguez, Global Product Manager - Large Blasthole

Epiroc's electric-driven blasthole drills offer a safer and more efficient drilling experience, in line with the company's dedication to sustainability. These new Pit Viper drill rigs show Epiroc's commitment to cleaner and more sustainable operations, boasting a smaller carbon footprint, zero exhaust emissions, and superior automation to deliver an optimized performance.

These drills deliver a more sustainable operation and are equipped with advanced automation, featuring smart functionalities that enhance operational safety, accuracy, and productivity.

Cynthia Rodriguez, Global Product Manager - Large Blasthole, expressed her enthusiasm, stating, “These electric-driven Pit Viper drills exemplify Epiroc’s unwavering commitment to accelerate change in the mining industry.”

“By combining advanced automation solutions with sustainability, we are offering state-of-the-art drills and paving the way for a safer, more efficient future in mining operations,” added Cynthia.

The introduction of these three drills signifies Epiroc's electrification of its complete Pit Viper lineup, providing electric alternatives for each drill in the series. Epiroc is poised to transform industry benchmarks, setting a new standard for environmentally conscious and technologically advanced mining solutions.

These drills deliver a more sustainable operation and are equipped with advanced automation, featuring smart functionalities that enhance operational safety, accuracy, and productivity.