Drilling targeted key areas defined for planned site infrastructure to confirm absence of mineralization and suitability for development.

Marimaca Copper Corp. (TSX: MARI) announced the completion of the infrastructure condemnation drilling program. The program was designed to test and confirm the planned site layout to be incorporated into the Company’s ongoing permitting and Definitive Feasibility Study (“DFS”) workstreams. Drilling targeted key areas defined for planned site infrastructure to confirm absence of mineralization and suitability for development.

Highlights

- Twenty-one reverse-circulation (“RC”) drill holes completed across the planned Marimaca Project infrastructure areas

- Drilling was designed to confirm the absence of potential mineralization at these areas, as well as rock suitability for development

- Drilling confirmed suitability of planned layout for plant site, heap leach pads, waste dumps, site offices and ripios dumps (spent heap leach ore)

- Layout will be incorporated into the design component of the ongoing Definitive Feasibility Study, led by Ausenco (see press release dated October 30th, 2023)

- Drill hole, SLR-08, drilled south of the planned plant facilities in the San Lorenzo district, intersected 30m at 0.99% CuT from 62m within a broader zone of 68m at 0.51% CuT from 62m

- Represents a new zone of mineralization encountered at the Marimaca Project

- San Lorenzo is located approximately 4km from the Marimaca Oxide Deposit (“MOD”) and represents a separate and distinct mineralized zone

- Results will be incorporated into future exploration plans and continue to demonstrate the significant discovery potential and exploration optionality at the broader Marimaca Project

- Initially planned for one of two initial areas identified for ripios dumps, the San Lorenzo area will be evaluated further for mineralization potential to ensure operational flexibility for future development

- The Marimaca Oxide Project DFS remains on schedule for late 2024 completion with permit submissions targeting the middle of 2024

Hayden Locke, President and CEO, commented: “With condemnation complete, we are confident in locking in our plant and infrastructure locations for both permitting and the Definitive Feasibility Study. We have used the information from this program for the dual purpose of confirming ground conditions to underpin expected civil earthworks estimation. This confirms that the site has good ground conditions and civil earthwork is as expected in previous studies.

“The discovery of a new mineralized trend identified in the San Lorenzo area will be evaluated further to determine next steps, but it appears the core zone extends to the south away from the project’s infrastructure and offers an interesting target for shallow oxide mineralization. Further afield, we have completed a review of our broader exploration package and have identified several areas with exciting potential. We are finalizing 2024 exploration plans particularly for the Sierra de Medina project and will update as new developments occur.

“We continue to progress the permitting and DFS workstreams to our planned timelines, in partnership with Ausenco, with target delivery dates of the middle and end of the year respectively.”

Program Objectives

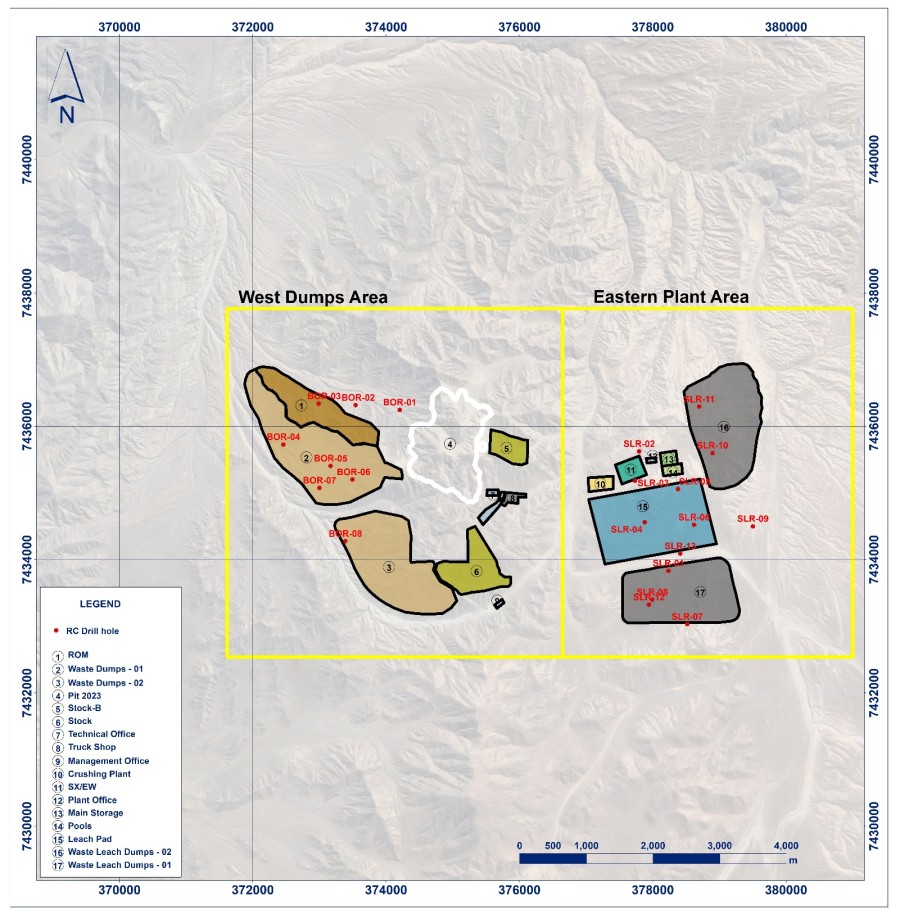

The condemnation program totaled 3,350m across 21 drill holes completed over two sectors, east and west of the MOD. The west sector targeted the areas planned for the waste dump and run-of-mine leach facilities, while the east sector covered areas planned for the installation of the crushing, SX-EW, heap leaching, ripios dumps and office areas. A high-resolution mag-drone survey was completed in advance of the drilling program to identify priority areas (within the planned infrastructure zones) for drilling.

Based on results from the program, the entirety of the west sector can proceed with planned DFS design due to lack of prospective mineralization. The zone corresponds to the outermost western halo of Marimaca’s IOCG alteration-mineralization system and is considered low potential for hosting mineralized zones of sufficient scale. A total of 8 drill holes totaling 1,200m were completed in the western sector.

In the eastern sector, areas planned for permanent site infrastructure (SX-EW plant, crushing facility, offices, heap leach pads) can proceed as defined. In the central zone of the Ripios 1 area, known as San Lorenzo, three holes (SLR 01, 13 and 08) intersected mineralized copper oxides along a NNE structural corridor identified in surface mapping and magnetic surveying. Mineralization appears to be hosted by veins and veinlets controlled by the contact regions of dykes and host monzodiorite. The nature of the lithology, alteration and mineralization assemblages resembles an IOCG system similar to that of the MOD. No prior drilling has been completed in this area. As such, further exploration work will be planned for the San Lorenzo zone during detailed engineering, however there is sufficient expected operation flexibility with the availability of other planned ripios areas to continue with development as planned.

Figure 1: Condemnation Program Overview: Site Layout

Figure 2: Condemnation Program Overview: West Sector

Figure 3: Condemnation Program Overview: East Sector

Table 1. Summary of Significant Intercepts

| Hole | Depth (m) | From (m) | To (m) | Intercept (m) | %CuT | |

| SLR-01 | 150 | 48 | 60 | 12 | 0.35% | |

| SLR-02 | 150 | 70 | 82 | 12 | 0.41% | |

| SLR-03 | 150 | No significant intercepts | ||||

| SLR-04 | 150 | No significant intercepts | ||||

| SLR-05 | 150 | 34 | 44 | 10 | 0.46% | |

| SLR-06 | 150 | No significant intercepts | ||||

| SLR-07 | 150 | No significant intercepts | ||||

| SLR-08

| 200

| 38 | 130 | 92 | 0.39% | |

| Including | 62 | 130 | 68 | 0.51% | ||

| Including | 62 | 92 | 30 | 0.99% | ||

| SLR-09 | 150 | No significant intercepts | ||||

| SLR-10 | 150 | No significant intercepts | ||||

| SLR-11 | 150 | No significant intercepts | ||||

| SLR-12 | 250 | 168 | 178 | 10 | 0.21% | |

| SLR-13 | 200 | 50 | 64 | 14 | 0.24% | |

| BOR-01 | 150 | No significant intercepts | ||||

| BOR-02 | 150 | No significant intercepts | ||||

| BOR-03 | 150 | No significant intercepts | ||||

| BOR-04 | 150 | No significant intercepts | ||||

| BOR-05 | 150 | No significant intercepts | ||||

| BOR-06 | 150 | 52 | 60 | 8 | 0.20% | |

| BOR-07 | 150 | No significant intercepts | ||||

| BOR-08 | 150 | No significant intercepts | ||||

Table 2. Drill Collars and Survey

| Drill Hole | Elevation (m) | Northing | Easting | Azimut | Inclination | Final Depth (m) | Sector |

| BOR-01 | 870 | 7,436,246 | 374,208 | 90° | -60 | 150 | West |

| BOR-02 | 775 | 7,436,317 | 373,546 | 270° | -60 | 150 | West |

| BOR-03 | 726 | 7,436,340 | 372,989 | 90° | -60 | 150 | West |

| BOR-04 | 722 | 7,435,728 | 372,462 | 270° | -60 | 150 | West |

| BOR-05 | 809 | 7,435,406 | 373,170 | 0 | -90 | 150 | West |

| BOR-06 | 854 | 7,435,201 | 373,500 | 90° | -60 | 150 | West |

| BOR-07 | 805 | 7,435,076 | 373,004 | 310° | -60 | 150 | West |

| BOR-08 | 876 | 7,434,278 | 373,391 | 0 | -90 | 150 | West |

| SLR-01 | 1147 | 7,433,833 | 378,238 | 270° | -60 | 150 | East |

| SLR-02 | 1082 | 7,435,623 | 377,799 | 310° | -60 | 150 | East |

| SLR-03 | 1086 | 7,435,185 | 377,736 | 270° | -60 | 150 | East |

| SLR-04 | 1117 | 7,434,561 | 377,883 | 270° | -60 | 150 | East |

| SLR-05 | 1112 | 7,435,058 | 378,384 | 270° | -60 | 150 | East |

| SLR-06 | 1109 | 7,434,523 | 378,624 | 270° | -60 | 150 | East |

| SLR-07 | 1177 | 7,433,032 | 378,519 | 310° | -60 | 150 | East |

| SLR-08 | 1137 | 7,433,399 | 377,996 | 310° | -60 | 200 | East |

| SLR-09 | 1101 | 7,434,500 | 379,505 | 0 | -90 | 150 | East |

| SLR-10 | 1056 | 7,435,599 | 378,899 | 0 | -90 | 150 | East |

| SLR-11 | 1070 | 7,436,294 | 378,698 | 0 | -90 | 150 | East |

| SLR-12 | 1142 | 7,433,325 | 377,946 | 270° | -60 | 250 | East |

| SLR-13 | 1112 | 7,434,091 | 378,415 | 310° | -60 | 200 | East |

Sampling and Assay Protocol

True widths cannot be determined with the information available at this time. DDH holes were sampled on a 2m continuous basis, halved by a conventional core splitter on site with one half sent to the Andes Analytical Assay preparation laboratory in Calama and the pulps then sent to the same company laboratory in Santiago for assaying. Samples were prepared using the following standard protocol: drying; crushing all sample to -1/4” and passing through a secondary crusher to better than 80% passing -10#; homogenizing; splitting; pulverizing a 400-600g subsample to 95% passing -150#; and a 125g split of this sent for assaying. All samples were assayed for %CuT (total copper); %CuS (acid soluble copper). A full QA/QC program, involving insertion of appropriate blanks, standards and duplicates was employed with acceptable results. Pulps and sample rejects are stored by Marimaca Copper for future reference.

Qualified Person

The technical information in this news release, including the information that relates to geology, drilling and mineralization was prepared under the supervision of, or has been reviewed by Sergio Rivera, VP of Exploration, Marimaca Copper Corp, a geologist with more than 35 years of experience and a registered member of the Comisión Minera (Chilean Mining Commission), as well a member of the Colegio de Geólogos de Chile, Instituto de Ingenieros de Minas de Chile and of the Society of Economic Geologist USA, and who is the Qualified Person for the purposes of NI 43-101 responsible for the design and execution of the drilling program.

The QP confirms he has visited the project area, has reviewed relevant project information, is responsible for the information contained in this news release, and consents to its publication.